Preventing MSDs in a quality improvement process

Preventing musculoskeletal disorders (MSDs) in a company also contributes to developing a sustainable process for improving quality of work life.

How do we define quality of work life?

According to the World Health Organization (WHO), quality of work life “refers to actions that allow for both the improvement of working conditions for employees and the overall performance of companies.”

Many organizations concerned with preserving the well-being of their employees are thus committed to a continuous improvement process across different workstations. However, in their desire to act, some companies are unsure of how to best integrate MSD prevention into this process, leaving them without solutions.

To address this, MOOVENCY has decided to offer an analysis of this process, explaining the steps of continuous improvement, along with a concrete illustration of the right approach to take.

Shall we delve into the topic?

Integration of MSDs at the heart of a continuous quality improvement process

In the context of continuous quality improvement, everyone is motivated to implement the right approach, but how do we move from willingness to action? Several key steps need to be identified and implemented to prevent MSDs among your employees.

1 – Study of MSD risks

To develop a concrete action plan, it is essential to prevent MSDs and identify the most demanding tasks in a work environment. Many employees may encounter difficulties due to pain generated at a workstation, which is why risk assessment is necessary.

With the intervention of ergonomists (internal or external to the organization), various ergonomic assessments can be conducted to map out the different risks and factors of MSDs in a workstation.

Everyone is motivated to implement a risk prevention process, but how do we move from political willingness to action? Let’s get to it !

2 – Ergonomic adjustments

Now that the constraints of a workstation are identified and following analysis reports, it is time to prioritize future prevention measures and make recommendations for adjustments.

Ensure that future adjustment solutions reduce the physical strain on operators, alleviate the most stressed joints while promoting more natural and safe movements.

Don’t forget about the general organizational aspects of the workstation (team rotation, workstation organization review, etc.), product and personnel flows, and psychosocial risks. These are also aggravating factors that must be considered for the approach to be sustainable over time…

3 –Training & awareness

The action plan is now being implemented, and workstations are being adjusted to reduce risks. And now?

In the continuity of this prevention, it is now imperative to implement training and awareness sessions on MSDs for your employees; why? Not all employees have the same level of knowledge about these risks or the same perception, even though they are confronted with them daily.

Raising awareness and training an employee on the prevention of MSDs also engages them in your continuous improvement process. A concerned employee will be more attentive and vigilant to risk factors.

An essential advantage to a process of improving quality at work, isn’t it ?

4 – Integrating employees into a collective approach

In this desire to involve employees in preventing MSDs, adopting a collective approach is a continuous quality improvement challenge; how?

Quite simply, in the same effort as awareness, involving employees in co-design workshops, asking them about their physical feelings, and conducting daily assessments with them reinforce employee mobilization. Employees are now at the heart of the MSD prevention process and genuine actors in the continuous improvement approach.

5 – Continuous Evaluation

To ensure the sustainability of all actions taken, now make way for regular monitoring of results using various performance indicators, whether they are quantitative (measurable by numbers) or qualitative (surveys, interviews, questionnaires, etc.).

These indicators will allow you to assess the situation and evaluate working conditions in line with your objectives and : do the recommendations need to be revised ? Are the indicators moving in the right direction?

This regular evaluation will enable you to ensure good follow-up and strengthen your various fields of action.

These are the main key steps of MSD prevention in the overall process of quality improvement. Thanks to this, organizations, regardless of their activities, can improve the work environment while also increasing productivity while meeting their objectives.

But concretely, how does this happen in practice ? Let’s discover together through a concrete illustration how MOOVENCY and KIMEA solutions contribute to preventing MSDs in a continuous improvement approach.

USE CASE – Continuous improvement

Let’s take the case of a company in the industrial sector, with fewer than 50 employees. The objective of the management is as follows : to support a quality improvement project associated with optimizing the biomechanical stresses on operators in their workstations.

Thanks to a previous evaluation of the constraints at workstations (carried out using KIMEA tools), the risks have already been identified. However, a question remains: How can we be sure that the proposed corrective actions will not hinder the company’s objectives? Let’s explore the approach taken by our organization:

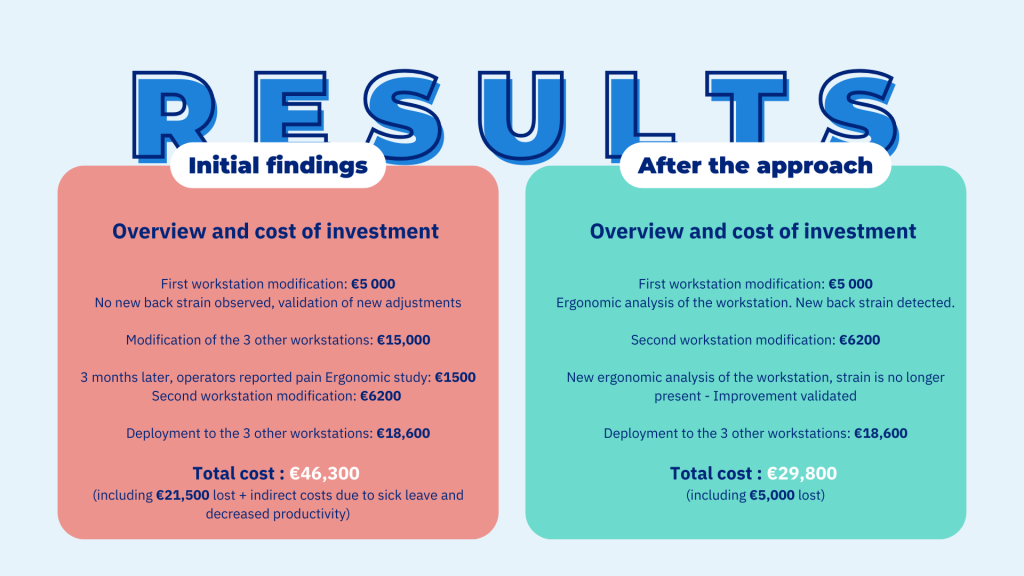

What results can be drawn from this?

The results obtained include:

- Direct and indirect savings of €16,500

- A well-framed ergonomic action plan

- Optimized project duration

- Reduction in sick leave

- No loss in productivity

- But above all, a respected and nourished continuous improvement approach.

This illustration highlights the importance of addressing MSD factors within a continuous improvement approach.

Thanks to KIMEA solutions, particularly the automated scoring calculation on the KIMEA CLOUD platform, integrating MSDs into the process allows for both direct and indirect cost savings. Any organization can thus envisage and structure sustainable actions for its employees.

Preserved quality of work life, risks avoided.

What if tomorrow it were your turn to take the plunge and integrate MSD prevention at the heart of your quality of work life improvement approach?

MOOVENCY supports you in MSD prevention and offers turnkey or customized services to quantify risks. Our mission is to help companies take ownership of their prevention approach within their organization and the actions to be taken for their employees.