NF X35-109 Standard: Understanding, Applying and Evaluating

Manual handling activities are among the most common tasks in the workplace, affecting all sectors of activity. These activities pose a significant risk to workers’ health, particularly in terms of the development of MSDs and occupational accidents.

In 2020, 589,833 occupational accidents were reported in France, and nearly 50% of them were related to manual handling tasks. This highlights the critical importance of implementing safe practices and appropriate assessment tools.

To prevent the risks associated with manual handling, the French standard NF X35-109, developed by AFNOR, provides a rigorous methodology for analyzing, assessing, and limiting physical strain during the lifting, carrying, and moving of loads. Let us now explore this standard and how it can be implemented to improve workplace safety and ergonomics.

NF X35-109: Origins and Use

NF X35-109 is a French standard developed by AFNOR in the field of ergonomics and the prevention of occupational risks related to manual handling of loads. It follows on from earlier work initiated with the experimental standard X35-109, published in April 1989, which it replaced.

Adopted in its current form in 2009 and revised in 2011, NF X35-109 was designed to provide a standardized analysis tool enabling the measurement, comparison, and prevention of risks associated with manual handling tasks. It addresses both immediate constraints likely to cause occupational accidents and long-term repetitive constraints that can lead to occupational diseases.

The standard applies to all activities involving the lifting, carrying, moving, pushing, or pulling of loads and takes into account the conditions under which these actions are performed.

NF X35-109: Assessment Criteria

The recommendations of the NF X35-109 standard are established for reference conditions. Within this framework, the standard defines reference threshold values, expressed according to the situation, in terms of:

→ unit loads

→ cumulative tonnage

→ exerted forces

→ or forces in relation to the frequency of actions

These criteria apply to operations involving lifting, lowering, carrying, placing, pushing, or pulling a load.

When the reference conditions are not met, the standard provides for the application of correction coefficients (CCs), intended to adjust the threshold values in order to take into account the increased level of strain.

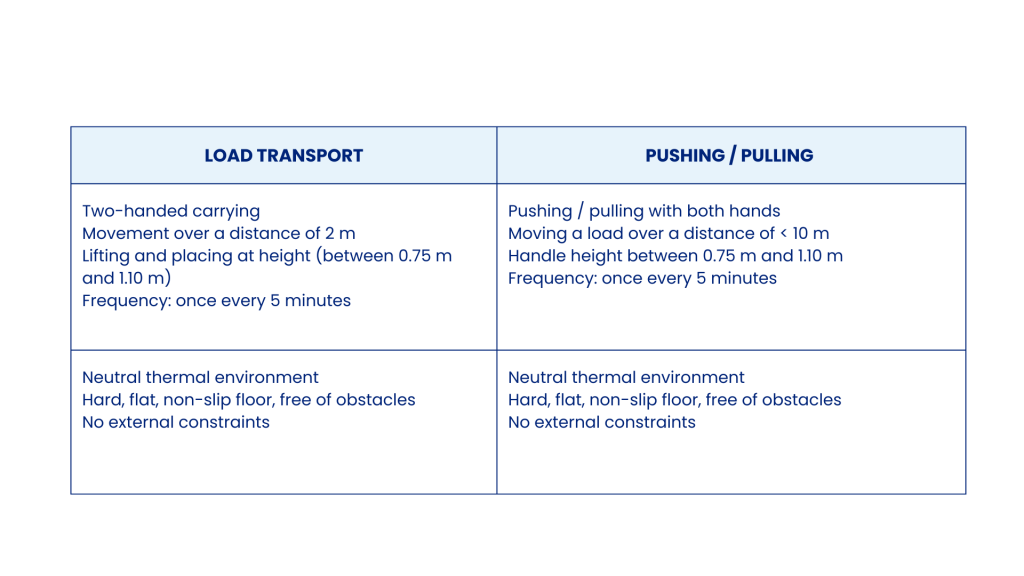

Reference conditions for manual handling

These are material, physical or organisational conditions that increase stress and give rise to increased risk.

The standard has therefore defined a list of five correction coefficients (CCs) in order to recalculate this reference value in relation to reality.

Note: To recalculate the new threshold value, only the two most penalising factors are taken into account.

These CCs include the following elements:

→ Height at which the effort is applied when picking up and putting down the load (take the worst-case scenario)

→ Distance travelled between picking up and putting down

→ Other conditions for performing the task: container without handles or with unsuitable handles, twisting of the trunk, outside the reach zone, one or more constraints concerning body posture/position, unstable load, limited visibility due to the load, etc.

→ Environmental conditions of the task: thermal, acoustic and lighting constraints, vibrations, dust, damaged floors, clutter, obstacles, inadequate space for manoeuvring, condition of the trolley.

→ Task organisation conditions: time constraints, reduced room for manoeuvre, quality requirements, multiple tasks, other work characteristics (shift work, isolated work, atypical working hours, unscheduled tasks, etc.).

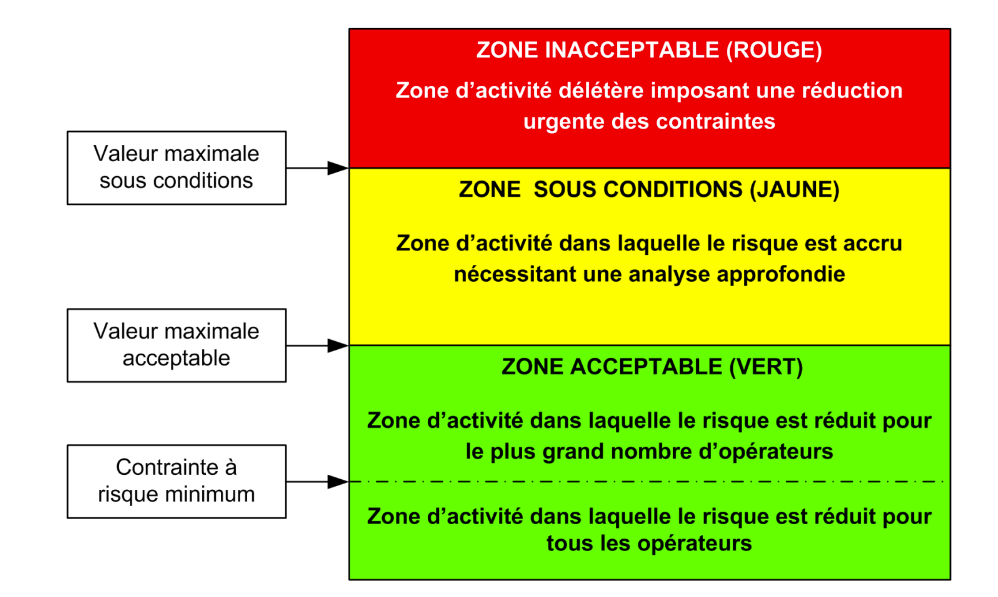

NF X35-109: Risk Levels

The NF X35-109 standard defines different levels of risk. These may be classified as:

“minimum,” “acceptable,” “acceptable under conditions,” or “unacceptable.”

The green zone corresponds to manual handling activities that are designed to protect the greatest number of workers.

The yellow zone corresponds to activities that present a risk and require specific preventive measures (this requires an in-depth analysis of the actual work activity).

The red zone corresponds to exceptional activities considered to be harmful, which require an urgent reduction of constraints to an acceptable level.

Table in french version

NF X35-109: Threshold Values

As mentioned previously, the NF X35-109 standard defines reference threshold values applicable to operations involving lifting, lowering, carrying, placing, pushing, or pulling a load.

Based on the 3 identified risk zones (green, yellow, and red), these values are defined in terms of:

-

unit loads handled,

-

cumulative daily tonnage,

-

pushing and pulling forces, expressed according to the duration of exertion, generally ranging from 1 to 5 minutes.

With:

-

Initial force: the force required to set the load in motion

-

Sustained force: the force required to maintain the movement of the load once it is in motion

NF X35-109 : Limits

Several limitations apply to the standard:

→ It only concerns the working population aged 18 to 65, without any restriction of physical ability and without distinction of sex (previously 15 kg for women and 25 kg for men).

→ It doesn’t apply when manual handling is performed on stairs or slopes.

→ The standard cannot be applied if the load is less than 3 kg. In such cases, it’s recommended to refer to NF EN 1005-5.

→ NF X35-109 does not account for cumulative stress from multiple different manual handling tasks (unlike NIOSH).

Finally, NF X35-109 is a voluntary standard and does not have mandatory compliance for companies. It’s not included in the Labor Code, so companies are entitled not to base their practices on this standard.

NF X35-109: Application cases

The NF X35-109 standard is primarily used in sectors where manual handling of loads is frequent and represents a significant risk factor.

The most affected professions include:

-

Construction and public works;

-

Personal care and medical assistance, involving the mobilization of people;

-

Transport and logistics: loading and unloading for storage of products, goods deliveries;

-

Retail;

-

Industrial and household waste collection;

-

Food processing.

In practice, the standard is applied during the analysis of workstations, the design or reorganization of a workshop, or as part of an initiative to prevent musculoskeletal disorders (MSDs). It helps evaluate whether a manual handling task is acceptable under given conditions, identify risk situations, and justify the implementation of corrective measures.

Example: the case of logistics

In a logistics warehouse, operators handle packages daily during receiving, order picking, and shipping operations.

NF X35-109 can be used to analyze a workstation involved in order picking that requires manual lifting of boxes over short distances.

The analysis involves checking whether the working conditions align with the reference conditions defined by the standard: weight, carrying distance, frequency of handling, and lifting/lowering height. When the observed values exceed the acceptable limits, or when additional constraints are present, correction factors are applied.

The results of the assessment can lead to various preventive actions.

This may include reducing the weight of packages, reorganizing picking areas, adjusting storage heights, improving pathways, or introducing handling aids (carts, lift tables).

The standard thus helps to quantify physical constraints and justify layout decisions to the company’s stakeholders.

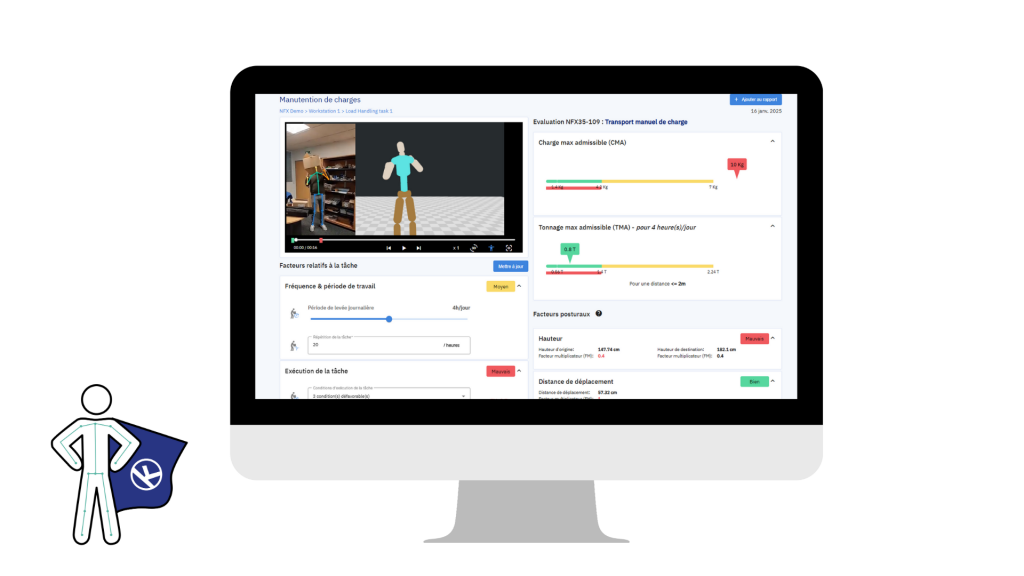

KIMEA, a comprehensive scoring grid

Several MSD risk indicators are integrated into Kimea Cloud, enabling automated calculation of physical risk scores. The grids used are the ergonomics reference grids: RULA, REBA, NIOSH and NF X 35-109.

Our project module, “Load Handling” is designed to assess the weight of loads handled and the daily tonnage managed by operators, in order to determine whether it complies with load handling evaluation standards and does not pose one or more risks of musculoskeletal disorders (MSDs). This module incorporates NF X35-109 in its calculations and allows you to…

-

To enter multiple task parameters;

-

To access several global indicators and analyses by level (manual handling task / project);

-

And to automatically calculate various factors related to the task.

Why have we brought together all these analysis methods?

Simply put, to offer you a more precise and tailored result for all types of workstations. We also wanted to measure the exposure time at each risk level.

Conclusion

NF X35-109 is an essential reference tool for assessing risks associated with manual handling of loads. By relying on clearly defined reference conditions, quantified threshold values, and a structured logic for classifying risk levels, it allows for an objective evaluation of the physical demands involved in lifting, carrying, pushing, or pulling loads.

However, its deliberately standardized scope and strict conditions of use highlight the need to complement it with other approaches when working situations deviate from the reference conditions or involve multiple constraints.

Discover our related articles on the topic

Sources :

AFNOR – Norme NF X35-109 – Ergonomie – Manutention manuelle de charge pour soulever, déplacer et pousser/tirer – Méthodologie d’analyse et valeurs seuils. Versions de 2009 et 2011

Moovency – Ressources internes

Palamatic Process – Manutention manuelle de charges : réglementation et facteurs à risque : https://www.palamaticprocess.fr/blog/manutention-manuelle-de-charges-reglementation-et-facteurs-risque

Passeport Prévention – Les chiffres clés de la santé sécurité au travail https://passeport-prevention.travail-emploi.gouv.fr/actualites/les-chiffres-cles-de-la-sante-securite-au-travail#:~:text=589%20833%20accidents%20du%20travail,50%20%25%20dus%20aux%20manutentions%20manuelles

SSTRN – MANUTENTION MANUELLE : Prévenir les risques rachidiens : https://www.sstrn.fr/sites/default/files/2023-12/sstrn-prev_guide_manutention_manuelle-sstrn-ge001.pdf