Construction Industry: Are MSDs on the Rise?

The construction industry presents particular working conditions: underground or confined spaces, heavy lifting, extreme temperatures, use of complex machinery and tools, exposure to chemicals, and constrained postures. In short, there are many risk factors that can cause musculoskeletal disorders (MSDs) among construction professionals.

In fact, the numbers speak for themselves: 92% of work-related illnesses in the construction industry are MSDs. Moreover, there’s a 20% increase in MSDs every year. These MSDs also lead to numerous sick leaves, as 9 out of 10 sick leaves are related to this occupational disease, resulting in nearly a million lost workdays.

(Source : preventica.com)

It’s also worth noting that the “blue-collar” branch of the construction sector is the most affected by MSDs, especially masons, roofers, and carpenters.

Faced with these findings, one might wonder if MSDs are inherent to the construction sector. Are they the price to pay for building everything that surrounds and connects us? And is it inevitable? Let’s assess.

A Plurality of Risks with Severe Consequences

Repetitive Movements

The decree of March 31, 2011, defines repetitive work as “repeating the same gesture at a constrained pace, imposed or not by the automatic movement of a part or by piece-rate pay, with a defined cycle time.”

Whether one is an electrician, a decorative painter, a carpenter, a heating installer, or a locksmith-metalworker, this decree applies. The movements performed during the activity are often repeated and identical. And therein lies the problem.

Indeed, the movement will strain one or more joints of the worker (wrist, shoulder, elbow, etc.) and cause microtraumatic events, recurrently and over time. This is why the risk of developing MSDs increases when the frequency of action exceeds 40 technical operations per minute.

Furthermore, since 2015, the law specifies that repetitive movements are risk factors for occupational hazards.

Awkward Postures

Beyond the repetitive aspect of gestures performed by construction professionals, the question of posture also arises.

Indeed, construction trades generally involve operations that are very demanding on the human body. Installing a roof, for example, requires significant range of motion and prolonged and risky working positions.

Psychosocial and Environmental Risks Should Not Be Overlooked

When discussing autonomy, meaning in work, just-in-time production, work complexity, leeway, or customer relations, we are then addressing psychosocial risk factors for employees in the construction industry. These factors are integral to their daily lives, shaping each of their days.

The consequences are numerous, both for employees (musculoskeletal disorders, professional burnout, depression, anxiety, suicide, etc.) and for the company (high absenteeism rates, significant turnover, degradation of productivity and quality).

Description of the Consequences of Psychosocial Risks Workers are also subject to climatic constraints, particularly cold weather, which exacerbates biomechanical factors. Additionally, it’s important not to forget that construction industry employees are regularly exposed to chemical products such as asbestos, smoke, or cutting dust.

Complex Working Conditions: The Example of a Construction Company

It’s important to emphasize that the risks of MSDs are not solely a matter of biomechanics, and the construction industry is no exception. The working conditions in this field also have their own complexity.To support our argument, we will present the results of an intervention conducted within a roofing company.

The objectives of this intervention were twofold:

- Work on optimizing the working conditions of employees

- Improve the performance of the company

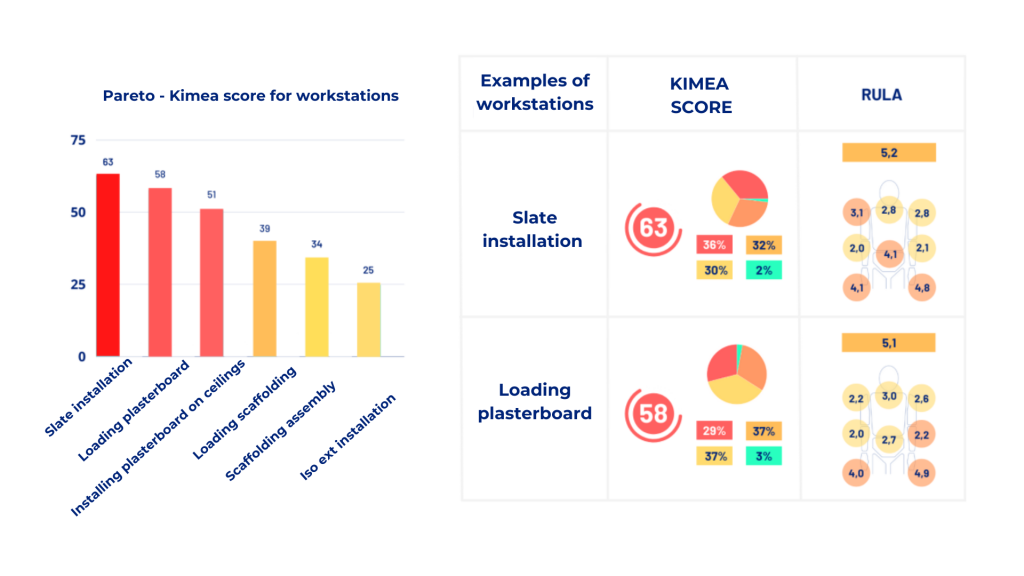

Initially, the KIMEA analysis highlighted the biomechanical demands on various operations carried out by the workers of this company.

In our example, we can observe that the lower back and wrists are heavily taxed, posing a real risk of developing MSDs.

Based on the quantitative data from KIMEA, we were able to unfold our intervention method to explore other factors. Thus, we sought to understand how the organization constrains movement. We also questioned which organizational, psychosocial, or environmental factors influence movement and increase biomechanical constraints.

Communication about shared client files, order management, external interventions, role definition, training, information tracking… We identified various issues in this company. This organizational disorder leads to numerous consequences:

- unforeseen worksites;

- internal conflicts;

- increased travel;

- forgotten or duplicate orders;

- and increased biomechanical constraints…

Strategies to Initiate a Prevention Policy in the Construction Industry

Thoroughly Prepare and Monitor Worksites

Organizing in advance to supply materials closest to the workstations can help limit manual handling. The aim is to avoid surprises that lead to physical strain on workers. Preparing worksites also helps to limit intermediate supplies and thus off-site movements.

Furthermore, regular monitoring of worksites will allow all employees to fully engage in the organization of the company. This monitoring can be done during weekly meetings where a document will present:

- client information;

- quotation number;

- supplies;

- expected date and dedicated team;

- preliminary interventions;

status of orders with potential suppliers.

These meetings could also be an opportunity for workers to report any problems encountered during the execution of their tasks.

Use Appropriate Equipment

Tools such as hand trucks, edge clamps, or carts can help eliminate or reduce manual handling. Some tools have also been designed to reduce the risk of MSDs, for example, those that limit the vibrations of certain tools.

Warehouses can also be rearranged to bring about real improvements in the daily lives of workers. For example, by increasing the storage capacity of a warehouse and reorganizing it, it’s possible to easily reduce multiple handling of raw materials, or even eliminate most of the handling altogether.

Optimizing the handling of heavy loads

In order to limit the risk of back pain, such as a herniated disc, it is necessary to handle loads while respecting some simple principles:

- be stable on your legs;

- face the load;

- bend your knees;

- grip the load firmly;

- lift it with a straight back;

- and bring the load as close to the body as possible.

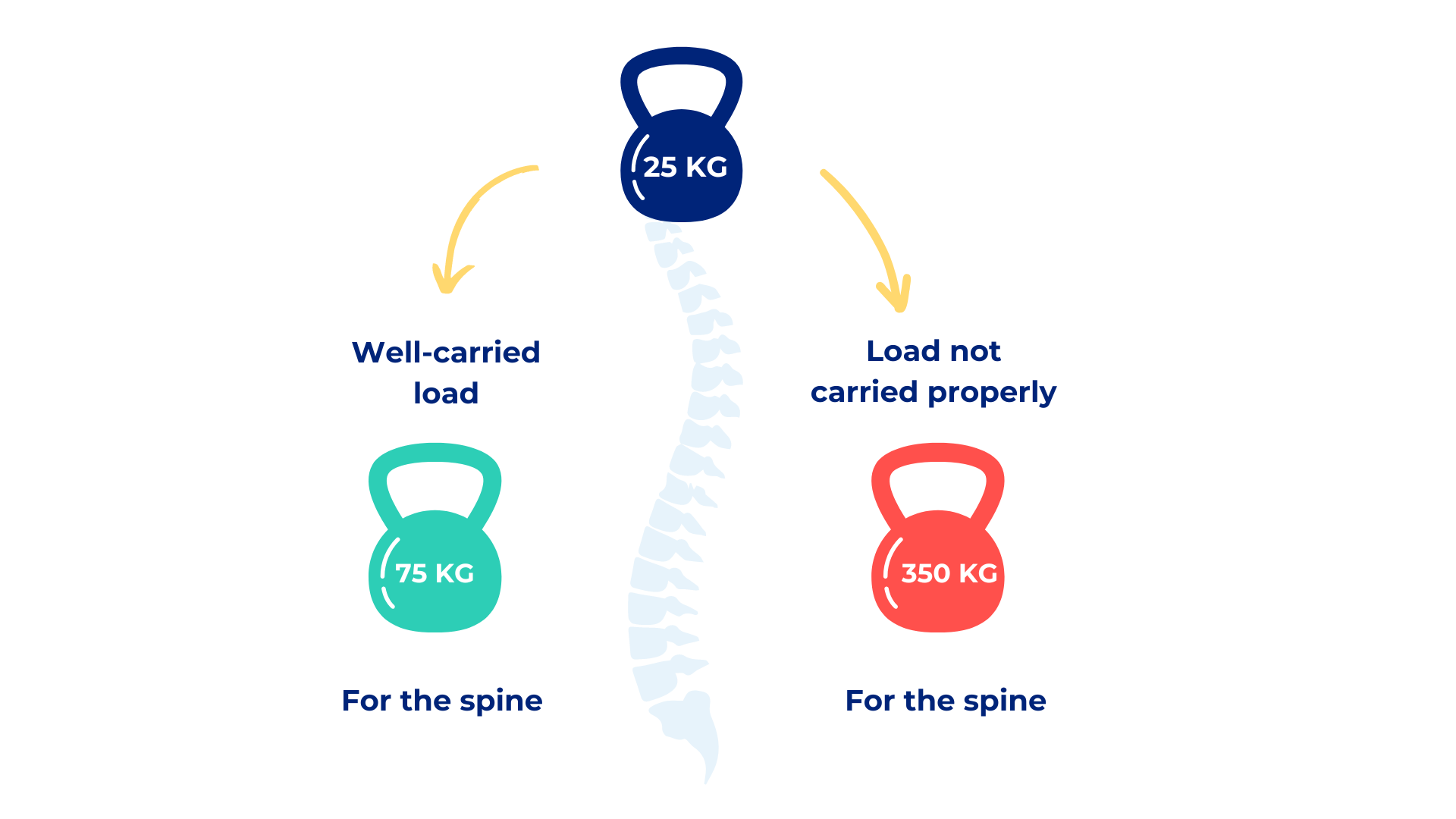

Indeed, a properly carried load of 25 kg will represent 75 kg for our spine. Whereas, if carried incorrectly, with rounded arms and back, the pressure of the same load will represent 350 kg on the companion’s spine.

However, it is important to remember that “there is no such thing as the right gesture.” It is the combination of organizational measures, combined with precautionary principles, that will help minimize the risk of lower back pain.

Involving workers in the process

It is important to note that companions are not the only ones choosing the gestures they perform daily. Indeed, they compromise between the company’s performance objectives, the material and human resources at their disposal, and their health.

By involving companions in the prevention of MSDs, we ensure its real success. They are the ones who know the work, their tasks, and their constraints the best. Therefore, they are best able to express the problems encountered in the structure and will also be very relevant stakeholders when seeking solutions.

With a tool like KIMEA, you can involve your companions in your prevention process with ease. Our KIMEA Cloud solution will allow you to film them with your smartphone to reliably measure the biomechanical risks of MSDs. No need for sensors: your workers will not be disturbed in their work.

Finally, the results via the application, including the KIMEA score and the 3D digital twin of the companions, will help you put words to the pains. You can try KIMEA Cloud today: enjoy thirty days of trial to discover your new tool!”