How to prevent MSD risks in the aeronautics industry ?

The question was raised by the Safran Helicopter Engines group. Let’s discover together the feedback on a case study involving our ergonomist Romane and Olivier Larcheron, ergonomist at Safran Helicopter Engines.

The group : Safran Helicopter Engines

Company overview

As a subsidiary of the SAFRAN group, Safran Helicopter Engines is the world leader in helicopter propulsion. With over 5,800 employees worldwide and 3 sites in France, their main mission is to provide unwavering support to their customers to take off their helicopters using the group’s engines.

Thus, facing this major challenge, the question of preventing musculoskeletal disorders (MSDs) is at the heart of the company’s issues.

The challenges of prevention and MSDs at Safran Helicopter Engines

Since 2012, the group has been implementing the “Ergonomics Safran” program and developing various commitments, such as a 5-year roadmap for integrating ergonomics into industrial activity and health prevention.

Different actions and tools have since been deployed by Safran Helicopter Engines, but these remain limited with a variability effect, causing a lack in the evaluation of biomechanical risk factors.

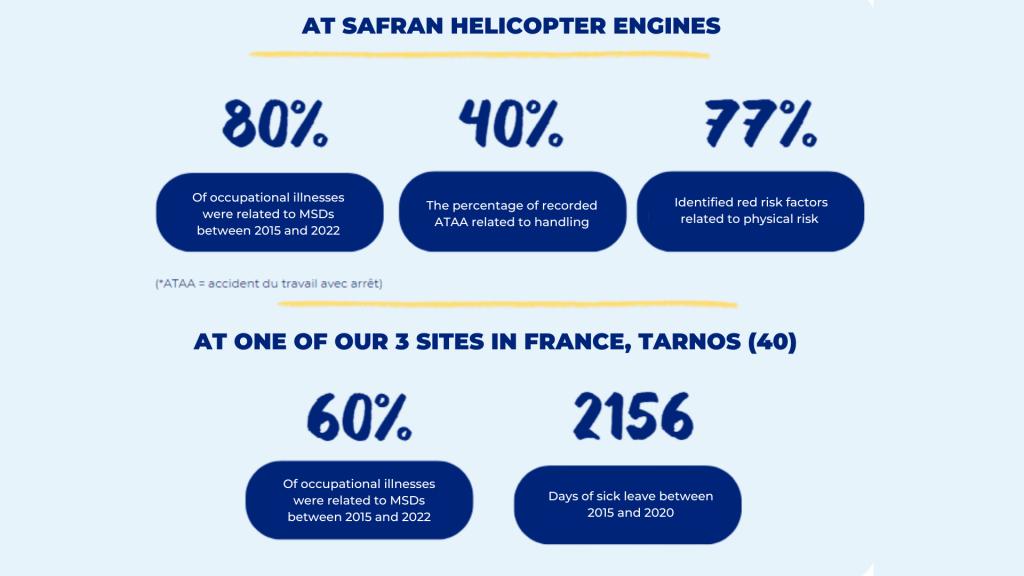

These risk factors present challenges related to accident rates at the group’s French sites:

At the Tarnos site, for operators and technicians, helicopter engine motorization relies mainly on maintenance and workshop activities: 70% involve manual activities and 30% are related to machinery.

Due to these activities, the presence of musculoskeletal disorders (MSDs) is increased for these employees, affecting them at all ages. A significant portion of these employees are aging, making them more susceptible to these MSDs and thus resulting in a higher turnover rate.

These alarming data thus push the group to redirect the focus of tools towards a more detailed analysis of risk factors to improve on-site needs.

Safran Helicopter Engines has thus considered several avenues for implementing concrete actions and has turned to the introduction of preventive solutions through KIMEA tools.

The KIMEA Solution : A case study review

The gradual integration of the tool

Since 2019, Safran Helicopter Engines & Moovency have initiated a collaboration with the KIMEA tool. Discovering the tool, internal positioning, technical questions, and ergonomist support have thus punctuated the collaboration.

Over two years, we tested the KIMEA tool together to identify and prioritize use cases for its optimal deployment.

Our use case

Here is one of the use cases that notably allowed for an effective and comprehensive use of the KIMEA tool for Safran Helicopter Engines.

JOB RETENTION & RETURN TO WORK

In the context of job retention and return to work, the focus shifted towards the inclusion of disabilities and employee health issues, faced with certain restrictions from the professional health physician.

Two main questions arose: Was the position adapted to the employee? In the situation of returning to work, was there a position suitable for the needs of each employee?

Faced with these challenges, the process unfolded in several steps:

- Assessing the feasibility of job retention and/or return to an adapted position.

- A three-step ergonomic analysis, including:

- A level 1 analysis based on the Occupational Health and Risk Assessment Document (DUERP) :

- An ergonomic analysis of the position and the machinery.

The main objective was to collect data and observe the risk factors of each position. Subsequently, to further analyze, the measurements obtained by the KIMEA capture tool confirmed that the position was compatible with the restrictions issued by occupational health.

Therefore, KIMEA served through data to validate the return to work in this employee’s position.

This complementary analysis allowed for:

- Identifying other moving joints ;

- Observing the joints most stressed by the worker in real-time ;

- Identifying the score on the Rapid Upper Limb Assessment (RULA) scale and thus considering possible workstation adjustments.

Based on the KIMEA data, we could see that the shoulder was indeed not significantly stressed, unlike the wrists. This led to a collective reflection, enabling the development of a tool to assist with tightening to relieve the wrists of all operators.

Thus, we transitioned from an individual situation to a shared exchange among the various stakeholders on-site.

Safran Helicopter Engines & Moovency

Our evolutionary approach

Today, the collaborative approach between Safran Helicopter Engines & Moovency has evolved; a true support system has been established as the tool has developed, addressing technical questions and incorporating suggestions from both parties.

The use of the tool has transitioned from primary prevention to tertiary prevention, from individual situations to collective initiatives across all Safran Helicopter Engines sites.

The added value of KIMEA lies in facilitating discussions on operating procedures among various stakeholders to trigger awareness and adaptation actions.

Our future outlook

What’s next ?

For the future of KIMEA at Safran Helicopter Engines, the goal is to deploy the tool and its practices across multiple companies within the group and internationally within the scope of Safran Helicopter Engines.

Another avenue would also be the digitalization of Safran Helicopter Engines’ ergonomic tools with the support of Moovency.

Thank you

Thank you to Romane Repessé and Olivier Larcheron for this feedback, whose webinair replay dated September 12, 2023 is available right here :