5 misconceptions about MSDs

“MSDs are just a matter of doing the right thing… And it’s normal: the working population is aging! This inevitably leads to an increase in musculoskeletal disorders. There’s no point in launching prevention campaigns: they’d be too costly for the company and would harm workers’ productivity. Simply reduce their movements, and that’s it! “

… Is it true?

We hear (all too) regularly statements of this kind: unfortunate assumptions which unfortunately harm the health of operators and, ultimately, the company itself. So, to put an end to preconceived ideas, we bring you the right answers.

Popular belief #1

“MSDs are only a question of the right gesture”.

While professional gesture is recognized as the key to preventing musculoskeletal disorders, this does not mean that there is such a thing as THE right gesture or THE right posture.

In fact, each operator creates his or her own operating modes by making his or her work his or her own. The gestures and postures he adopts are the result of a compromise between the demands of the job and the time available to perform it. And, unfortunately, the compromise will always be posture.

For example, it’s easy for an operator to tell himself that he’s not going to use this or that object or method, because – according to his perception – he’d be wasting time.

MSDs are therefore not just a question of good gestures, because operators are aware that their gestures can damage their health.

Moreover, the risk of MSD must not be reduced to a purely biomechanical notion. Other factors are also involved:

- Individual factors ;

- Environmental factors ;

- Psychosocial factors;

- Organizational factors.

It’s also a good idea to train your employees in professional gestures. By working with them to develop “efficient” gestures, i.e. those that are the most effective while requiring the least effort, you will reduce the risk of impact on their health.

Finally, it is essential to call on the skills of an ergonomist, who can determine the origin of the problems encountered by operators and the determinants of risk.

Popular belief#2

“The ageing of the working population inevitably leads to an increase in MSDs.”

It’s true that the working population is ageing more and more, and that age is an aggravating factor. But age isn’t everything. It’s not an obligation, a compulsory box for all workers. In fact, any company is capable of preventing MSDs throughout an operator’s career, and thus preserving his or her health right up to retirement.

How can this be achieved?

By implementing appropriate preventive measures as soon as a new operator arrives. Companies that know how to support their employees, reduce physical constraints and optimize their workspace will find that age is no longer a problem.

Popular belief #3

“The less you move, the fewer MSDs you contract“.

It’s easy to believe that by reducing operators’ movements, the risk of developing MSDs would be reduced… But that would be a mistake.

Reducing movement also means reducing the space and power available for action… And yet, the body needs movement to be healthy. The human body is designed to move, to circulate blood and eliminate toxins. Movement also keeps all tissues (muscles, tendons, joints…) in shape, thus preventing RSI.

What’s more, if an operator doesn’t move, he’s probably been assigned to a single task. He has only one thing to do at his workstation. He therefore lacks autonomy and has no room for manoeuvre. This also greatly increases the risk of contracting MSDs.

COMPANY PERFORMANCE VS. PREVENTION OF MUSCULOSKELETAL DISORDERS (MSDS)

Popular belief #4

“Reducing MSDs means reducing the company’s profitability.”

To improve a company’s profitability, we systematically think of increasing operator productivity or making cuts here and there in the budget. At Moovency, we’re convinced that these two solutions are no longer the only ones on the table. Indeed, investing in MSD prevention in your company means investing in its future and profitability.

What’s more, an increase in an operator’s productivity, if not anticipated in its entirety, can be detrimental to the company: degradation of product quality and of the operator’s health.

What if we considered MSD prevention as an obstacle to productivity? What if we started from the premise that MSD prevention is synonymous with industrial productivity?

Taylorian productivity standards need to be humanized. We need to think differently about productivity. Rather than focusing on the speed at which operations are carried out, we need to think about how an operator can meet complex quality and performance requirements over time.- Pierre Plantard, co-founder of Moovency.

Popular belief #5

“MSD prevention is too expensive”.

Preventing MSDs, yes… But at what cost? This is the question many companies ask themselves, believing that the investment is far too high. And yet, MSDs entail a number of costs of which few managers are aware.

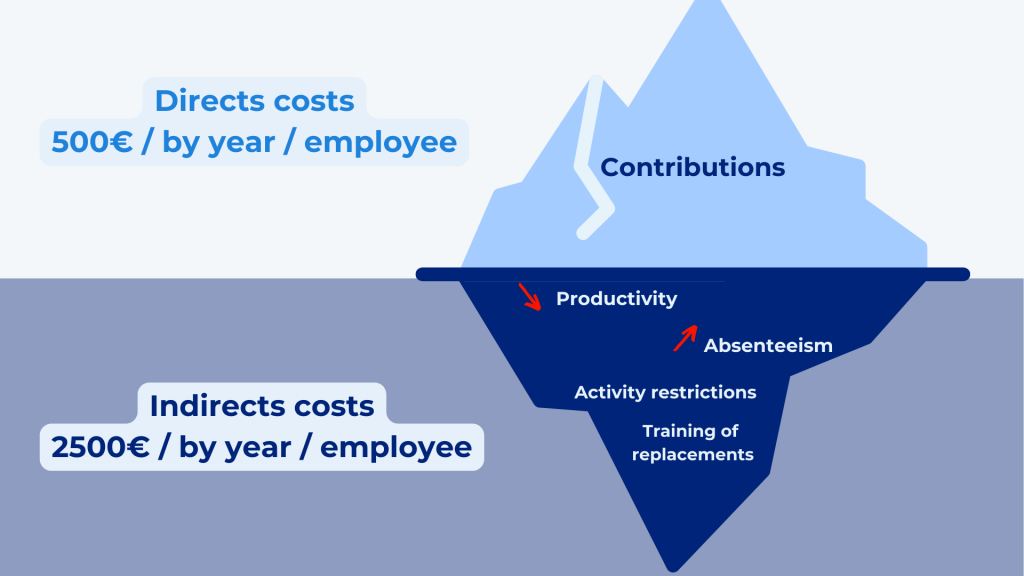

On the surface, the cost of MSDs is around 500 euros per year per employee. This corresponds to the contributions companies have to pay. However, the hidden face of the iceberg reveals an altogether different reality: indirect costs.

Reduced productivity, increased absenteeism, activity restrictions, training for replacements: all these are just the consequences of MSDs, and cost almost 2,500 euros per year per employee.

The reality of this preconceived idea is quite different. Failure to prevent MSDs in the workplace is costing companies a great deal of money… and irreversibly damaging operators‘ health.

In addition, financial aid is available to help companies reduce work-related accidents and illnesses in France. At Moovency, we’ve identified those that might be right for you:

- the TMS Pro diagnostic program ;

- the TMS Pro Action program;

- simplified financial assistance (AFS);

- the Fonds d’Amélioration des Conditions de Travail ;

- and the prevention contract.

Contact us to find out more!