When productivity Wears Down the Body: MSDs in Assembly Line Work

The example of the automotive industry

The assembly line revolutionized industry by enabling fast, standardized, and profitable production. But behind the productivity figures lies a less flattering reality: musculoskeletal disorders (MSDs), conditions that affect muscles, tendons, and joints.

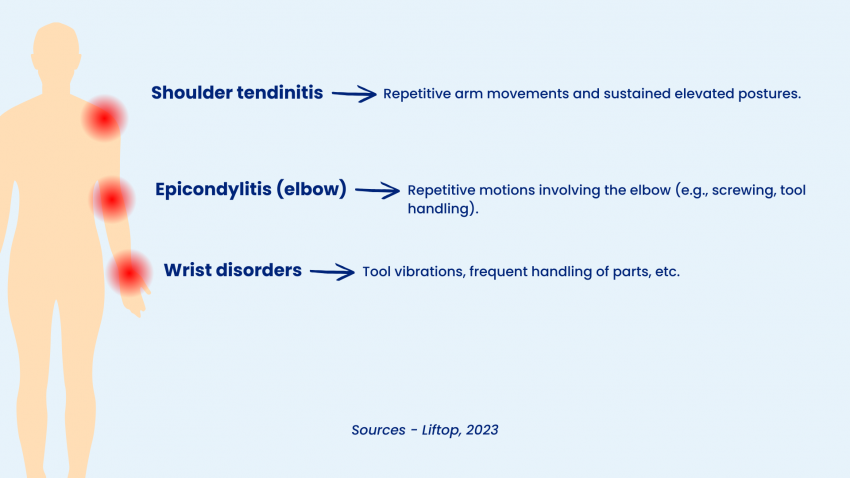

Shoulder pain, burning wrists, stiffening backs… These symptoms often appear subtly, until they become chronic.

How does assembly line work—designed to maximize productivity—end up silently wearing down workers’ bodies to the point of causing chronic pain and reduced performance?

I) The automotive industry: A model of productivity… and physical strain

Since the early 20th century, the automotive industry has perfected the art of the assembly line. In modern factories, every workstation is timed down to the second. Long or highly repetitive cycles—such as fitting doors, assembling wiring harnesses, or tightening components—ensure a smooth production flow… but force operators to repeat the same motions hundreds of times a day.

The result : an increased risk of musculoskeletal disorders (MSDs).

II) Long cycles : An aggravating factor for MSDs in the automotive industry

In the automotive industry, a long cycle refers to a work sequence in which the operator repeats the exact same motion for several minutes—sometimes dozens of times per hour—before the part moves on to the next stage of the line. This type of organization is extremely effective for maintaining a steady pace of production, but it places significant strain on the human body.

- First, the lack of muscular variation is a major issue: the same tendons, joints, and muscle groups are engaged continuously, without enough time to recover. Whether it’s tightening a component, positioning a windshield, or attaching a door, the identical repetition of movement creates mechanical stress always on the same area, sometimes hundreds of times a day.

This excessive repetition leads to an accumulation of microtraumas. These are small, initially invisible lesions—tendon inflammation, muscle tension, joint compression—that progressively weaken tissues. As long as the operator continues working on the same cycle, the body has no chance to repair these micro-injuries, accelerating the onset of musculoskeletal disorders.

- Added to this is the constraint of industrial pace. In automotive plants, each workstation is synchronized with the vehicle’s passage time. This leaves very little room to slow down, adjust a movement, or release muscular tension. Operators must maintain speed, even when fatigued or in pain, which intensifies both the physical and psychological burden.

The effects of this organization are not felt immediately : the wear is insidious. The first warning signs—stiffness in the back, shoulder discomfort, wrist pain—are often dismissed as temporary fatigue. But as weeks and months pass, the pain becomes chronic. To keep up, operators unconsciously adapt their gestures, which shifts strain to other parts of the body and creates new tensions.

Gradually, this spiral results in decreased precision, longer execution times for certain operations, and even a rise in errors and accidents. What was designed to optimize productivity ultimately ends up undermining it.

III) Pathways to prevention in the automotive industry

Reducing MSDs in the automotive sector is not just about reacting once pain has set in: it requires daily preventive action, integrated from the very design of workstations and the organization of work cycles.

This involves several complementary levers: task variation to limit continuous strain on the same muscles, ergonomic optimization of workstations, adjustment of production pace, and raising awareness among all production stakeholders about the early signs of physical fatigue.

To make this approach effective, it is essential to rely on objective analysis tools.

This is where KIMEA comes in—our range of solutions developed to evaluate postures directly at the workstation, in a fast, reliable, and non-intrusive way. In just a few minutes, you can identify the body areas under the most strain, quantify biomechanical constraints, and generate actionable data to adjust the height of a workstation, rethink a repetitive motion, or redesign the sequence of a cycle.

Moovency also supports companies beyond simple measurement :

- Personalized guidance to integrate solutions without slowing down production.

-

Training and awareness initiatives so that every operator can recognize and report the first signs of an MSD.

By combining a strong prevention culture with technological tools like KIMEA, it becomes possible to reconcile industrial pace with health preservation. This proactive approach transforms MSD prevention from a regulatory obligation into a genuine driver of performance and sustainability in the automotive industry.

Conclusion

Assembly line work in the automotive industry, with its long cycles and repetitive motions, represents a major health risk for operators. MSDs, often silent at first, gradually take hold, leading to chronic pain, physical compensations, and declining performance.

Fortunately, prevention can change this reality. By combining workstation optimization, training and awareness programs, and technological tools, it is possible to protect operators while maintaining productivity. Acting upstream—identifying risk areas and adjusting work movements—not only reduces MSDs but also strengthens performance and quality on the production line.

Investing in prevention is therefore not just a health necessity: it is also a strategic lever for building a sustainable and efficient automotive industry.

Sources :

> https://pharesst.irsst.qc.ca/rapports-scientifique/402/

> https://www.autoprevention.org/fr/themes-sst-details/troubles-musculosquelettiques-tms-aux-membres-superieurs#:~:text=De%20nombreux%20travailleurs%20dans%20le,possible%20de%20pr%C3%A9venir%20ces%20troubles.

>https://www.liftop.fr/prevention-des-troubles-musculo-squelettiques-dans-le-secteur-automobile-5-strategies-efficaces/

> https://stoptms.com/blog/cout-tms-2025.html?utm_source=chatgpt.com