The deciphered biomechanical measurement tools

We know it: detecting musculoskeletal disorders (MSDs) risks isn’t easy. Multifactorial diseases, MSDs are never due to a single cause. And analyzing biomechanical risks is an important step in the prevention process. But the complexity of this task can quickly become discouraging… Not everyone is an expert in this field.

And to properly analyze biomechanical risks, and effectively prevent them… They must be properly measured. Yes, but how? With a biomechanical measurement tool, of course! To make things clearer for you, we’ve compared different rating solutions. Shall we go?

Biomechanics: Gateway to Analyzing MSD Risks

If you’re here, it might be because you want to implement a strategy to prevent MSDs. Or perhaps because you need to optimize the one you already have in place. And that’s a good thing.

If you aim to keep your employees safe and healthy, preventing MSDs will be your ally. And if you want to avoid all the costs associated with MSDs in your organization – direct costs, indirect costs, as well as intangible ones – it will even be your best friend!

The Importance of Equipping Businesses with Biomechanical Measurement Tools

As mentioned earlier, MSDs are multifactorial pathologies. Here, we will address one of the most time-consuming factors to quantify and qualify: biomechanics.

Repetitiveness of movements, excessive efforts, fine and precise gestures, durations of uncomfortable postures: there are many biomechanical risk factors. By studying how the body moves and interacts with its environment, biomechanics can help identify potential risk factors and develop strategies to reduce them.

Equipping businesses with a biomechanical measurement tool will save valuable time in their prevention of MSDs. They can focus more on other risk factors, such as organizational or psychosocial factors.

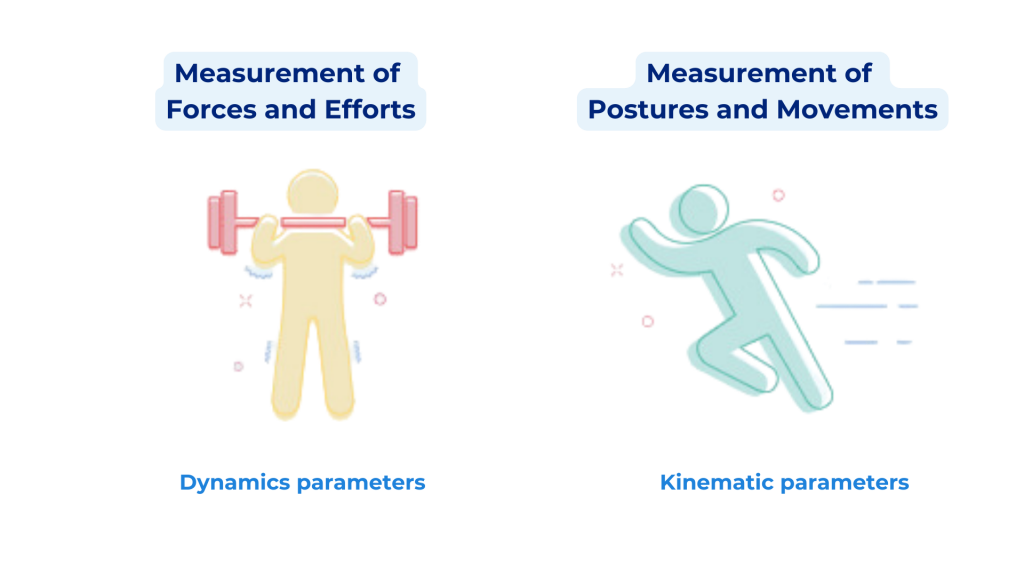

Measurement of Force and Effort

EMG or Electromyography (surface), a Popular Tool for Measuring Muscular Effort

EMG is the most widespread measurement instrument for assessing muscular efforts. It is often surface based, consisting of two electrodes that are attached to the skin. It measures the electrical activity of the underlying muscle to indirectly obtain its overall effort during contraction.

Advantages

✅ EMG is considered the gold standard tool for measuring muscular effort in laboratory settings.

Limitations

❌ EMG requires a certain level of expertise as it necessitates very precise anatomical placement.

❌ Implementation is cumbersome for production since electrodes must be positioned on the operator’s body, thus interrupting their work execution.

❌ Results are difficult to interpret directly in terms of MSDs. There is no direct standard linking measured electrical activity in a muscle to MSD risk.

MMG or Mechanomyography: Using Vibrations to Study Movement

MMG is a tool that measures the vibratory activity of muscles during contraction. Like EMG’s measurement of electrical activity, vibratory activity indirectly reflects the overall effort of the muscle during contraction.

Advantages

✅ MMG is less dependent on precise muscle placement compared to EMG.

✅ It more easily detects deep muscle activity.

Limitations

❌ Like EMG, placing sensors on the body is cumbersome.

❌ Interpreting risks are challenging. Measurements remain relatively evaluative.

❌ To date, there is a lack of scientific studies enabling widespread use, particularly in ergonomics.

Dynamometers for Comprehensive Biomechanical Measurements

Dynamometers are tools used to measure the forces exerted or experienced by an individual, often at the extremities – such as hands or feet. Among the most used are force platforms, pressure mats, or force sensors.

Advantages

✅ Dynamometers offer direct or near-direct measurements of forces.

✅ There are ergonomics standards available for comparison to established benchmarks.

Limitations

❌ Dynamometer measurements are highly localized to the extremities of the body.

❌ They do not reflect the intensity of effort at joints and muscles. Therefore, it is difficult to measure the muscular constraints that may lead to MSD risks.

Mathematical Modeling: Science Serving Biomechanical Measurements

The use of biomechanical or musculoskeletal modeling tools allows for the indirect estimation of the forces exerted on joints and muscles. They employ mathematical models based on movement or external forces applied to the operator.

To illustrate, let’s take the example of a cyclist. With mathematical modeling, it’s possible to indirectly estimate the forces of each muscle in the lower limbs based on the measurement of their movement and the force they exert on the pedals.

Advantages

✅ Mathematical modeling allows estimation at the level of deep muscles of the operators.

✅ It can be performed without a body-worn motion capture system.

Limitations

❌ Mathematical modeling is a complex tool, primarily limited to research at the moment.

❌ Computational time is significant (several hours of calculation per minute of measurement).

❌ It heavily depends on the measurement noise of movement data.

❌ Results are difficult to interpret directly in terms of MSD risk.

❌ There are no standards. Evaluation currently relies on comparing one situation to another.

CHOOSING THE RIGHT BIOMECHANICAL MEASUREMENT TOOL

Do we really have to choose between health and work? Should performance at work come at the expense of well-being? Are MSDs the cost we have to pay?

Measurement of Operators’ Postures and Movements

There are two sub-families of motion analysis tools:

- Sensors worn on the body;

- Optical-based systems, meaning measurement via one or more cameras.

Body-worn sensors for biomechanical measurement: the example of goniometers

Goniometers consist of two branches connected to a potentiometer or a strain gauge to measure a change in angle between the two branches.

To conduct the measurement, the two branches are placed on the two parts of the body connected by the joint to be measured. They notably show the joint amplitudes of operators.

Advantages

✅ It is a robust technology without occlusion issues.

Limitations

❌ Sensors need to be placed on the body, which can hinder operators’ movement. This can limit the “real” aspect of the work performed by operators and skew the results.

❌ They only measure joint angles. Positions are not included.

❌ There are often only 2 axes of rotation. And this is limited to joints such as wrists.

Body-worn Sensors: Focus on Magnetic Systems

Magnetic systems utilize sensors placed on operators’ bodies. They measure the magnetic field generated by an emitting source, allowing for the determination of each sensor’s position and orientation.

Advantages

✅ Magnetic systems do not suffer from drift errors over time.

✅ They do not encounter occlusion issues as seen in optical systems.

✅ They provide positions and orientations without requiring post-processing.

Limitations

❌ Sensors need to be placed on operators’ bodies, like goniometers. This imposes similar constraints, potentially impeding the operator’s movement.

❌ They are susceptible to electrical and magnetic interferences, which can be problematic for companies operating in industrial environments where metal presence is significant.

Body-worn Sensors for Biomechanical Measurements: Inertial Systems

Inertial Measurement Units (IMUs), also known as inertial sensors, are systems composed of sensors integrating an accelerometer, a gyroscope, and often a magnetometer. Each sensor provides the orientation of the body segment to which it is attached.

Advantages

✅ Inertial systems do not encounter occlusion issues.

✅ The technology is cost-effective.

✅ Inertial measurement units have a small form factor.

Limitations

❌ They still require sensors to be placed on the body, potentially hindering the operator and affecting production.

❌ Drift errors occur over time. The gyroscope may become misaligned with prolonged use. Although the magnetometer is present to correct these drifts, it is sensitive to magnetic and electrical interferences. This presents a similar issue to magnetic systems in industrial conditions.

❌ Inertial systems only measure orientations and do not provide positions.

❌ A cumbersome calibration process is necessary to obtain positions.

Optical-based Systems for Measuring Biomechanical Constraints: Optical-electronic Systems Scrutinized

Opto-electronic systems utilize multiple infrared cameras to reconstruct the 3D position of markers reflecting (passive) or emitting (active) infrared light.

These are the systems used to create synthetic images like those seen in movies such as Avatar or in video games like FIFA.

Advantages

✅ These systems are extremely precise, with an error risk lower than a millimeter.

✅ Opto-electronic systems do not have occlusion or drift issues.

Limitations

❌ These systems are very expensive – we’re talking about several hundred thousand euros.

❌ Opto-electronic systems require extensive expertise in post-processing, limiting their use to laboratories.

❌ Sensors need to be placed on the body. Alternatively, the operator can wear an entire suit. This proves cumbersome for operators and time-consuming to set up.

Optics: 2D Cameras and Computer Vision, an Effective Combo for Measuring MSD Risks

Computer vision enables the identification of operators in images captured by a camera and determines the positions of each of their joints. This is achieved using deep learning algorithms that have been learned, through vast amounts of example data, to deduce these postures from images.

Advantages

✅ 2D cameras are non-invasive for the operator and pose no constraints on production.

✅ No specific equipment required (low acquisition cost) – works with a smartphone.

Limitations

❌ Occlusion issues may arise.

❌ The accuracy of the data depends on the algorithm and training data.

Optics: 3D Cameras and Computer Vision as a Method for Assessing Occupational Risks

3D cameras are depth cameras. They provide in-depth information for each pixel of the image. The algorithm estimates the posture directly in 3D using this data.

Advantages

✅ Similar to 2D cameras, they are non-invasive for the operator and do not hinder company production.

✅ They are sufficiently precise for ergonomic assessment in the field.

✅ They provide real-time 3D positions of operators.

Limitations

❌ Like 2D cameras, they may encounter occlusion issues.

❌ Again, precision is dependent on the algorithm and training data.

Conclusion: What is the most suitable measurement tool?

This overview has allowed us to draw several conclusions. Let’s quickly recap what we’ve discussed together.

Regarding Sensors:

Force measurement tools are technologies that enable the indirect assessment of muscle efforts.

These remain complex tools that are challenging to use in industrial environments by non-biomechanists. This limits their use to laboratories and experts engaged in specialized service activities.

Furthermore, there is currently no method that directly links muscle effort to the risk of MSDs. Numerous other factors may come into play. However, it remains effective for comparing one situation to another to observe increases or decreases in muscle effort.

Regarding vision-based systems:

Optical systems do not have these issues since it is sufficient to track the person with a camera. However, occlusion problems can distort the capture.

Moovency’s Perspective on the Right Biomechanical Assessment Tool

Sensors, vision-based systems… Why choose ? This analysis has allowed us to discover the strengths and weaknesses of all biomechanical measurement tools. For us, the conclusion is straightforward. It’s essential to combine sensors and computer vision. We aim to bring together the best of both worlds.

That’s why we’ve conceived and created KIMEA. We have reinvented the prevention of MSD risks by offering a solution for quantifying biomechanical risks:

- Easy to use to adapt to all users.

- Non-invasive operators and production friendly.

- Equipped with multiple indicators of MSD risks.

- Reliable, with scientifically proven data.

- Considers the duration of operators’ exposure in calculating MSD risk.

For the field. For companies that care about the safety of their employees. And so that no one has to choose between their work and their health.