Handling Loads and MSDs: How to Respect Standards?

Whether in a warehouse, factory, or store, handling loads is one of the most commonly performed operations by employees in the secondary sector. And there are standards in place to preserve the health of operators.

What are they? And how can they be respected? Let’s take a look.

Handling loads and MSDs: what’s the connection?

Tasks and professions facing MSD risks

What do we mean by handling loads? This action involves the transportation of a load. It requires physical effort, which can be provided by one or more people. Generally, the operator(s) must:

- lift;

- place;

- push;

- pull;

- carry;

- or move the load.

Handling loads also includes actions performed regularly and iteratively by an operator when they need to position, grasp, or move machines or tools.

Among the professions most affected by handling loads are:

- Building and public works professions;

- Personal care and medical care professions, which generally involve mobilizing people;

- Logistics sector professions, where employees are involved in loading and unloading for product storage, or goods delivery;

- Professions related to industrial waste collection and household waste;

- Agri-food professions, such as slaughterhouses that involve carrying heavy carcasses;

- and so on.

Multiple Consequences Associated with Load Handling

It’s important to emphasize that the risks generated by load handling are significant in the professional world. Indeed, due to their nature, these operations can lead to numerous consequences for employees. We’re talking about…

– Bruises;

– Cuts;

– Fractures;

– Back pain;

– or muscle tears.

And all these ailments can even lead to the recognition of an occupational disease.

Combined with other risk factors—organizational, environmental, psychosocial risks, and human factors—they can lead the operator to develop a musculoskeletal disorder.

Indeed, load handling involves the three biomechanical factors of MSDs: effort, posture, and repetitiveness.

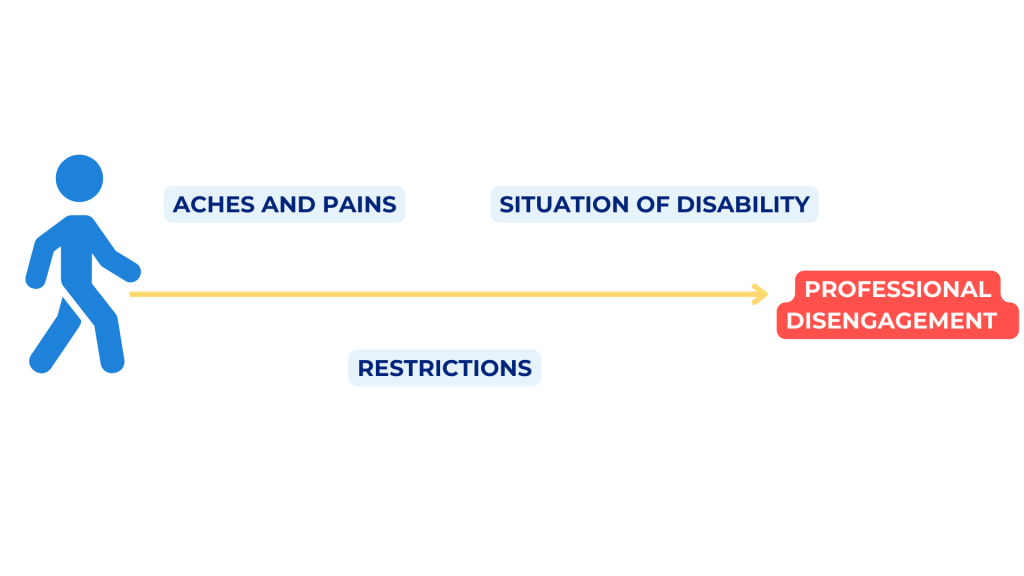

Beyond the pain and ailments mentioned earlier, MSDs can lead to a deterioration of the employee’s health and professional life.

Companies are also affected by the consequences of musculoskeletal disorders occurring among their employees. They have a significant impact on the overall performance of the company.

This includes absenteeism, replacement of human resources, decreased production quality, as well as the costs of training new employees or temporary workers.

These effects generally lead to an overall exhaustion of the workforce—and therefore more risks of new workplace accidents or MSDs—as well as tensions and conflicts. All of this damages the company’s image.

Standards related to load handling

The NF X35-109 standard

Recommended by the National Health Insurance Fund for Salaried Workers, the NF X35-109 standard analyzes activities related to load handling.

This standard sets limits on load carrying. Therefore, it indicates risk levels for employees and thresholds not to be exceeded.

The NF X35-109 standard is structured around the following risk levels:

– “minimum”;

– “acceptable”;

– “acceptable under conditions”;

– and “unacceptable”.

However, these levels are only references, meaning they are applicable only under optimal handling conditions. Corrective factors must then be applied to these risk levels, depending on the actual work of the operators, which implies a lowering of the weight recommended by the standard.

These corrective factors depend on several factors, including:

– the height of the effort application;

– the distance traveled with the load;

– environmental conditions;

– task organization;

– or any other factors specific to each company.

Additionally, the NF X35-109 standard can also determine a daily tonnage. This takes into account all the loads carried by an employee during a working day.

It’s important to note that this standard:

- Only encompasses activities known as “manual handling”;

- Concerns the active population aged 18 to 65, without distinction of gender;

- Cannot be applied in “degraded” work situations that may entail additional risks;

- And cannot be applied if the load is less than 3 kg.

The NIOSH Equation

It’s important to discuss the NIOSH equation in this article. It’s an assessment method used to analyze whether lifting a load by an operator is risky or not for them.

This equation can be used to evaluate lifting and lowering tasks performed by a person, using both hands.

The equation defines a Recommended Weight Limit (RWL), which is the heaviest load recommendation that a healthy worker can lift without increasing the risk of developing a musculoskeletal disorder, such as lower back pain, for example.

The NIOSH lifting equation takes into account weight as well as several other variables in lifting tasks that contribute to the risk of injury to operators. Several factors can decrease the RWL:

- The height of lift and lower;

- The distance of the load between lift and lower;

- The frequency of the action;

- Trunk twisting;

- or the quality of grip.

Once the calculation of the Recommended Weight Limit (RWL) is done, companies must compare it with the weight carried by the operator in actual working conditions. This is how the calculation of the Lifting Index (LI) can be performed.

The calculation of the Recommended Weight Limit (RWL) and the Lifting Index is done…

- For the original posture;

- And for the destination posture of lifting the load.

However, the equation cannot be used if the task is performed:

- With one hand only;

- For more than 8 hours;

- While seated or kneeling;

- Pushing or pulling;

- With wheelbarrows or shovels;

- In a confined workspace;

- With unstable objects, such as buckets or liquid containers;

- With high-speed movements – more than about 30 inches per second;

- With extremely hot or cold objects or in extreme temperatures;

- Or with poor foot-to-floor contact – especially with a high risk of slipping or falling.

The Labor Code

The Labor Code also takes into account manual handling performed by operators. The following elements are noted:

– The load tolerated for men must not exceed 55 kg.

– To be able to carry loads exceeding 55 kg, operators must have been recognized as “fit” by occupational health. However, these loads must not exceed 105 kg.

– Women, on the other hand, cannot carry loads exceeding 25 kg.

For more information, refer to articles D. 4152, D. 4153-39 to D. 4153-40, R.4541-1 to R. 4541-11 of the Labor Code.

The Social Security Code

Finally, Social Security also has a say in the issue of MSDs related to load handling.

This is why “Table 98” lists all MSDs and specific illnesses that employees may contract. This table also specifies the timeframes for coverage by Health Insurance. Moreover, “Table 98” provides a wealth of advice for companies to restrict the risk of contracting MSDs, particularly through its list of tasks to be carried out by companies.

How Moovency Helps Companies Meet Standards

Field Feedback that Raises Alarm

At Moovency, we’ve identified a real need among our clients. They require a tool that allows them to easily calculate the maximum permissible load for load handling activities.

Similar to posture-focused methods such as RULA or REBA, load handling methods should enable companies to compare the load values carried by their employees to specific thresholds. It’s essential for them to identify these limits and act accordingly if the value exceeds the recommended limit set by standards.

However, to detect these limits, companies must input (far too) many parameters to measure. This makes the process far too complex and time-consuming for ergonomists and prevention specialists.

Furthermore, these parameters are related to movements and postures, such as:

– The depth of grip and placement;

– Trunk rotation when placing the load;

– etc.

These parameters are therefore difficult to estimate with the naked eye.

From Automation to Simplification: The Contribution of KIMEA Cloud

This is where KIMEA comes in. With its ability to measure operators’ movements via video capture, the solution can automatically calculate these parameters. It’s the automation of measuring these kinematic parameters that motivated Moovency to address this real need encountered by its clients, for obvious reasons of performance and standardization of analysis.

Using the NF X35-109 standard or the NIOSH equation then becomes much simpler. Measurements can be made automatically, but also objectively and reproducibly.

Reliable, easy to obtain, and unambiguous, results from the NF X35-109 standard or the NIOSH equation become a significant asset for field professionals. Indeed, corrective actions to be implemented within a structure can be evaluated by KIMEA Cloud and thus become a strong argument to justify an investment.

And this is something that you too can implement within your company. Indeed, you can start a free trial of your new tool for quantifying the biomechanical risks of MSDs today: KIMEA Cloud!

Beyond Biomechanics: How a Comprehensive Approach Can Prevent Load Handling-Related MSDs

Of course, while biomechanics is an important factor in the development of musculoskeletal disorders in load handling actions, it’s important not to forget that MSDs are primarily a multifactorial disease. Our article “The Risk Factors of MSDs” can enlighten you on this point.

On these issues, Moovency can also assist you. Our four certified ergonomists IPRP travel throughout the country to support you in your MSD prevention efforts, particularly through the “Ergonomic Analysis” service.

Indeed, this service allows for the analysis of the various risk factors for MSDs faced by employees in a company.

By understanding the specific risk of MSDs for our client companies, our ergonomists can then focus on finding tailored solutions.

To learn more, feel free to contact us!